Thorium MSRs: A Path Towards Energy Swatantrya For India

A Path Towards Energy Swatantrya And Enhanced Economic Growth For Bharat.

Introduction

As we all know, the Indian economy struggles due to Energy imports. They’re responsible not only for causing our trade deficit but also hurting our diplomacy on the global stage. In this article we will discuss how Thorium Molten Salt Reactors can eliminate our Energy imports by virtue of their greater versatility compared to conventional nuclear reactors.

How do Conventional Nuclear Reactors work?

Conventional Nuclear reactors use Uranium-235, a radioactive isotope of Uranium, as fuel with steam at high pressure acting as the coolant and fluid for heat transfer to the turbines that spin to generate electricity. Some shortcomings of this process:

Since conventional nuclear reactors operate at 200-300 atm pressure, they need to be kept inside a pressure vessel, that is the concrete dome which is associated with nuclear reactors today. This pressure vessel has to be constructed onsite which turns each nuclear powerplant into a large engineering undertaking which doesn’t benefit from economies of scale.

While Uranium is abundantly available, U235 is only about 0.7% of all Uranium in the earth’s crust. Its about as rare as silver.

Uranium ore must be enriched through an expensive process to increase the U235 content in the fuel. Most reactors today use fuel which has 3-5% U235. Above 20% enrichment is considered weapons grade and would invite stringent international regulations

Since most reactors today operate at relatively low temperatures of 200-300 degrees Celsius, they’re relatively inefficient when it comes to converting thermal energy into electricity.

Where does Small Modular Reactor technology stand in India today?

Off late there has been a lot of discussion on Small Modular Reactor (SMR) technologies being implemented in India. The current discussion is on Bharat Small Modular Reactor (BSMRs) which will essentially be a repackaged version of our conventional Nuclear reactors which are Pressurized Water Reactors (PWRs) fuelled by Uranium-235.

The below image compares NuScale’s SMR (the 1st SMR technology approved by the US’s Nuclear regulatory authority) with a traditional PWR.

How is a Molten Salt Reactor different?

As the name suggests, a Molten Salt Reactor (MSR) is a nuclear reactor which utilizes molten salts in its operation. These molten salts serve as a solvent for the reactor fuel (uranium and/or thorium) and a carrier for the heat (>550 C) produced by the reactor. This heat can then be put to work running power turbines to generate electricity and/or running industrial processes.

Thus, MSRs operate very differently compared to PWRs and the upcoming Bharat SMR. MSRs can also be SMRs since the latter classification is based on capacity, manufacturing method.

History of Thorium MSRs

MSR research started with the U.S. Aircraft Reactor Experiment (ARE) in support of the U.S. Aircraft Nuclear Propulsion program. ARE was a 2.5 MWth nuclear reactor experiment designed to attain a high energy density for use as an engine in a nuclear-powered bomber.

The Molten-Salt Reactor Experiment (MSRE) further built upon the ARE. It was an experimental molten-salt reactor research reactor at the Oak Ridge National Laboratory (ORNL) in Oak Ridge, Tennessee. This technology was researched through the 1960s, the reactor was constructed by 1964, it went critical in 1965, and was operated until 1969.

Benefits of MSRs over Traditional Reactors

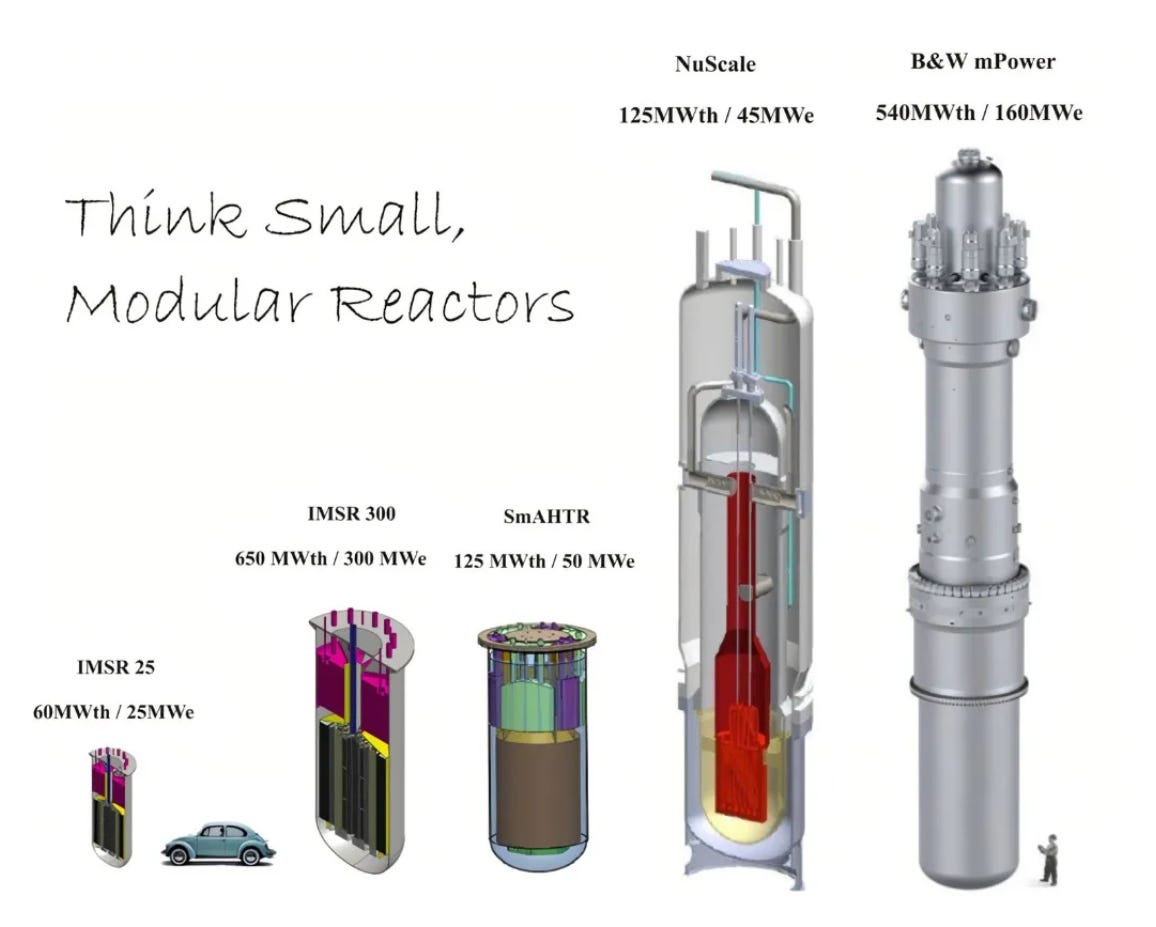

Conventional reactors are Pressurised Water Reactors (PWRs). These operate at 200-300 C and approx 200 atm pressure. In the below image you can see a size comparison of MSR designs (on the left) and modernised PWR designs on the right.

The key benefits are:

MSRs can be built much smaller and more modularly than conventional reactors. In fact, they can be built in a mass production facility, reducing costs and construction times considerably.

Depending on the design, MSRs can be refueled while they are operational. Meanwhile, conventional reactors have to be switched off for 1-2 months and refueled every 18 months.

MSRs use more than 90% of the energy content of their fuel while PWRs use less than 1%. Hence, MSRs generate a lot less waste and, more importantly, no long-lived waste.

PWR’s fuel needs to be manufactured in the form of rods containing fuel pellets. Thus, there is a cost involved in manufacturing the fuel for the PWRs. In contrast, depending on the design, MSRs can use fuel directly from the mines. This fuel is dissolved into the molten salt loop of the MSR.

PWRs can run only on enriched Uranium whereas, depending on the design, MSRs can operate on Thorium, Uranium and even PWR waste. This provides a strategic advantage since the fuel or its raw material may not need to be imported.

MSRs can easily and quickly change their power output while PWRs can’t. This makes MSRs more suitable for applications other than electricity generation. In this article, we’ll be exploring similarly novel non-power generation based applications for MSRs, the following is an image illustrating such novel applications.

The below image is taken from Thorcon’s (An MSR startup working in Indonesia) website and shows a size comparison of the steam generation unit at a traditional coal plant and the corresponding Thorcon MSR barge.

MSRs are much safer than Traditional Reactors

Elimination of a pressure vessel since MSRs operate at high temperature and low pressure while the opposite is true for conventional reactors. This reduces construction costs and operational complexity which increases the safety considerably.

When a PWR reaches the upper limit of its operating range, its reactivity increases leading to an uncontrolled chain reaction. In contrast, a MSR’s reactivity reduces at higher temperatures and increases at lower temperatures. Thus, the physics of a MSR self-regulates its operation.

Hence, MSRs are walkaway safe and unlikely to cause a nuclear accident. In contrast, PWRs need to be cooled actively. A MSR would shutdown by itself and not cause a nuclear event like Chernobyl. This also means that much less work must be done to make them safe, further reducing their cost of construction and operation.

The Indian Economy Struggles Due To Energy Imports

India has sizeable trade and fiscal deficits primarily due to its commodity imports and subsequent govt subsidies on the costs of these commodities.

India imports

50% of its natural gas requirement, 35% of its urea, 18% of its ammonia ( India Ammonia; anhydrous imports by country | 2019 | Data (worldbank.org) ),

90% of its crude oil

22% of its coal consumption (for electricity generation).

Replacing these commodities and energy imports with domestic production should be the 1st target. The outputs from MSRs can significantly reduce these imports.

How do MSRs allow for import substitution of these commodities?

The manufacture of Hydrogen is the first step in the production of Ammonia, Urea and Synthetic Fuels.

Current electrolyzer technology achieves about 50-55% efficiency. High temperature steam electrolysis enabled by an MSR easily achieves 92% efficiency. Hence, we can consistently produce Nuclear Based Hydrogen, called Red Hydrogen, at a cost of only $1/kg. See this video for more details on the topic:

In contrast, the global target for the production cost of Green Hydrogen is $2/kg.

Eliminating Natural Gas Imports

We consume about 29% of natural gas for fertilizer production, 19% for power generation, 20% for city gas distribution and the rest for other purposes include shrinkage, etc.

Luckily, India only needs to import half its natural gas consumption. The target uses which are relatively easy to replace would be fertilizer production and power generation. These amount to approx 50% of our natural gas consumption.

In the case of fertilizer production, natural gas is cracked into Hydrogen which is then used to make ammonia which, in turn, is used to produce fertilizers like urea. Instead of cracking natural gas to produce Hydrogen, MSRs can directly produce Hydrogen at low cost which can then used for further processing.

For power generation, natural gas plants are mainly used as peaker plants and hence, they have a fairly low plant load factor of 15% in FY24. However, MSRs can produce cheaper electricity through steam turbines. Hence, the need to import natural gas for such peaker power plants would be obviated.

We imported $31.8 Billion worth of LNG in FY24; this amounts to 0.6% of our trade deficit. Almost all of it can be eliminated.

Boosting domestic Ammonia and Urea production

As mentioned previously, one of the key uses for natural gas is fertilizers such as urea. Urea is manufactured from Ammonia which, in turn, relies on Hydrogen from natural gas as the key raw material.

By using Hydrogen produced by MSRs, we can bring the cost of ammonia down to 20% of current market price. Thus, the cost of urea production would also come down by a similar margin.

This would save approx $15.7B on urea subsidy alone, as per FY24 figures. This figure represents 6% of FY24 Central govt net tax revenue.

This process can be further optimized to become more efficient which will, in turn, reduce the cost of urea even further.

Eliminating Coal Imports

India imports about 22% of its coal consumption. This coal is used in thermal power plants to generate electricity.

The coal import bill during FY24 is estimated to be around $16 Billion. This figure represents approx 21% of our trade deficit .

We can decommission some of coal thermal power plants and install MSRs at those sites. This would also reduce our carbon emissions by 15%. Since most Imported coal thermal plants are situated on the coast or very close to ports, these sites can also house desalination plants which would utilize the MSR’s waste heat after power generation.

Replacing Crude Oil Consumption

Our gross crude oil Import bill came to $133 Billion in FY24. This is about 3% of our GDP.

A major portion of our crude is refined into petrol, diesel, etc. We consume most of these domestically and export the rest.

We can set up electrochemical plants which extract CO2 from seawater and crack the seawater into Hydrogen and oxygen using heat from the MSRs. Now, we have CO2 and Hydrogen, the basic building blocks for all the liquid fuels we burn. The US Navy has been working on a program to utilize dissolved CO2 in the ocean alongside Hydrogen to make jet fuel for the naval airplanes on its aircraft carriers. You can learn more about it here: https://www.smithsonianmag.com/innovation/fuel-seawater-whats-catch-180953623/

These can be recombined using the Fischer Tropsch process into a selection of custom fuels like synthetic petrol, diesel and jet fuel. According to the US navy lab working on the project, these synthetic fuels won’t have sulfur or nitrogen and have better performance characteristics too. Given the cheap energy from MSRs, we can produce these synthetic fuels at Rs 17-20/L. This is at least half the current market price of fuels produced from crude oil.

Here’s the fuel price breakup for the uninitiated:

Benefits of Eliminating Crude Oil Consumption

Since the fuel industry is well regulated by the govt, it can choose not to pass this cost reduction on to the consumers. This would effectively double the petroleum industry’s contribution to the Central exchequer.

The large-scale construction and operation of these seawater to fuel plants doesn’t mean that our sizeable crude oil refineries would shut down. They can continue to import crude oil and export refined petroleum products. Based on FY24 numbers, this would eliminate 230% of our trade deficit!

As far as CO2 emissions are concerned, this would reduce our carbon emissions by 14% with no adverse economic impact.

Reduction in CO2 Emissions

Replacing imported coal and decommissioning an adequate number of coal plants and replacing their generating capacity with MSRs would reduce our carbon emissions by 14.7%.

Replacing liquid petroleum fuels with synthetic versions of the same fuel would cut carbon emissions by 14.4%.

Replacing natural gas imports for fertilizer production with Hydrogen from MSRs would cut carbon emissions by 2.5%.

All in all, this comes to 31.5% reduction in Carbon emissions with a clear economic gain.

Total Economic Benefit

Replacing coal imports with MSRs removes 21% of trade deficit.

Replacing the consumption of petroleum based liquid fuels with synthetic fuels and exporting all domestic production of petroleum products eliminates 230% of trade deficit.

Replacing natural gas imports for fertilizer production with MSR powered H2 saves 41% of trade deficit and 6% of central govt tax revenues through less outgo toward fertilizer (urea) subsidy.

All in all, India could turn its trade deficit into a trade surplus! We could do this by simply substituting energy imports with products from MSR driven processes. The GDP growth is expected to increase by 5.84% due to the trade surplus of 3.83%. This makes us a double digit GDP growth economy!!

How much MSR Capacity is needed to do this?

By 2030, the power generation from imported coal is expected to grow to 55GW. Another 250 GW will be needed if all new power generation is to come from MSRs.

Also, by 2030, replacing all of our petrol, diesel and jet fuel consumption with synthetic variants would require another 220 GW.

As mentioned previously, natural gas imports are mainly used to produce Hydrogen and ultimately fertilizers through a sequence of industrial processes. Also, as mentioned previously, MSRs can used to produce Hydrogen more cheaply than the current processes. For this, the installed MSR capacity would be approx 15 GW in 2030.

All in all, we would need between 290GW and 540GW of MSR installed capacity.

Significant process optimizations in the manufacture of Hydrogen (for synthetic fuels and replacing natural gas imports) would reduce this figure by at least 10%.

Fuels Needed for MSRs

1 GWYear of power generation through Thorium MSRs consumes a maximum of 1 ton of Thorium annually.

Therefore, 290 – 540 GWYear of MSR operations would entail a consumption of 290 – 540 tons of Thorium annually.

Given India’s current Thorium reserves of 963,000 tons. We would have 3200 years of Thorium from our current land based reserves at these consumption levels

Which startups are working on Thorium MSRs?

Thorcon is a startup working to develop its MSR solution for Indonesia, they offer a prepackaged solution meant for power generation.

Copenhagen Atomics is a denmark based startup which offers micro modular reactors. These can be stacked up and used for process heating and power generation, both. Thus, there’s much greater flexibility in capacity and application.

Flibe is a US based startup which seeks to utilize all the benefits of MSR technology to the fullest by enabling spent fuel processing into revenue generating byproducts and online re-fuelling to maximize uptime.

Why is China at the forefront of this technology today?

China is building the world’s 1st demonstration unit of 10MW capacity in the Gobi desert, demonstrating the fact that Thorium MSRs dont need water like traditional PWRs. China would also be exporting this technology through its Belt and Road Initiative. See more here: https://visionias.in/current-affairs/news-today/2024-07-30/science-and-technology/worlds-first-thorium-molten-salt-nuclear-power-station-to-be-launched-in-gobi-desert-by-china-in-2025

Interestingly, China restarted its MSR program in 2011 after Kirk Sorensen, founder of Flibe Energy, uploaded a lot of documents from Oak Ridge National Lab about the Molten Salt Reactor Experiment to his website in 2008. He says that a number of chinese students would frequent his website to download soft copies of all the documents he had uploaded.

The Chinese program was funded with a few hundred million dollars in 2011 and put under the charge of Jiang Mianheng, son of Jiang Zemin, General Secretary of the Chinese Communist Party from 1989-2002. This shows just how serious Beijing has been about key technical R&D which serves a strategic purpose.

Would you mind sharing links to the files that Kirk Sorensen uploaded?

What is the benefits for Babus in this, if they can see their personal gain it will be on fast track